Why Scrapped Cars Still Matter to the Modern Auto Industry

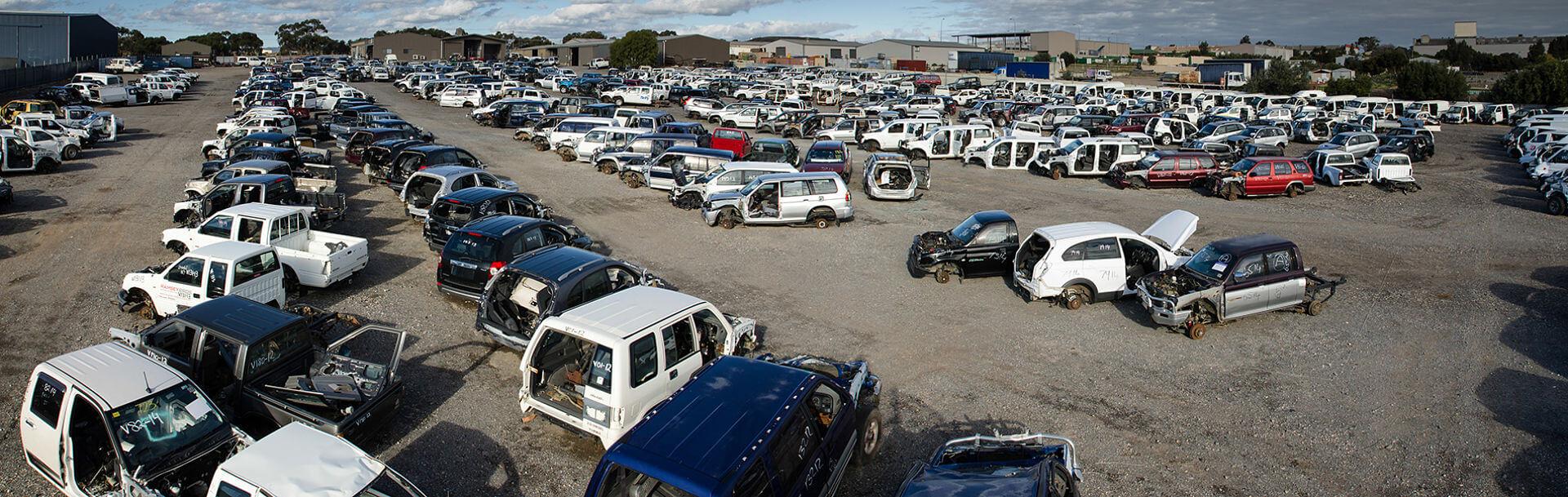

Many people see an old car as a dead machine. It may not start. It may sit in a yard. It may look useless. Yet this view misses an important truth. Scrapped cars still shape the modern auto industry in many ways. They support manufacturing, supply raw materials, and help control waste.

The auto industry does not only move forward with new models. It also depends on what happens at the end of a car life. Every scrapped vehicle carries materials, parts, and data that still matter today.

This article explains why scrapped cars remain important. It looks at recycling, parts reuse, steel supply, jobs, and environmental impact. All points relate to the current auto industry in Australia.

The Average Life of a Car

A passenger vehicle in Australia usually stays on the road for about ten to fifteen years. This range depends on use, service habits, and climate. After this period, many cars fail road checks or cost too much to repair.

When a car reaches this stage, owners often choose to scrap it. That decision starts a new phase in the car life cycle. The car stops driving, but it does not stop contributing.

Modern auto systems rely on this final stage more than many people realise.

Steel Recovery Still Drives Car Production

Steel makes up nearly sixty percent of an average car by weight. Even today, steel remains the main material for frames, panels, and safety parts.

Scrapped cars supply a large share of recycled steel. According to global industry data, recycled steel from old vehicles can reduce energy use by around seventy percent compared to new steel made from iron ore.

Australian steel processors depend on scrap input. This lowers pressure on mining and cuts industrial emissions. Without scrapped cars, steel plants would rely more on raw extraction.

So each old car helps build future cars.

Aluminium and Copper Matter Too

Modern vehicles use more aluminium than older models. This metal appears in engines, wheels, and body panels. Aluminium recycling uses far less energy than primary production.

Copper also plays a growing role. Wiring systems, electric motors, and sensors all need copper. Electric and hybrid vehicles use even more of it.

Scrapped cars act as a steady source of these metals. This supply supports current production needs and future design changes.

Reused Parts Support the Repair Market

Not every part in a scrapped car is worn out. Many engines, gearboxes, doors, mirrors, and electronic units still work well.

These parts enter the used parts market. Repair shops and car owners rely on them. This keeps older cars running longer and reduces the need for new parts.

In Australia, used parts help regional drivers. New parts often cost more in remote areas. Reused parts help keep vehicles on the road where transport options remain limited.

This system supports both drivers and workshops.

Scrapped Cars Reduce Industrial Waste

Cars contain plastics, glass, rubber, and fluids. If left untreated, these materials can pollute land and water.

Modern scrap processing separates these elements. Oils and coolants get drained. Batteries get handled with care. Plastics get sorted by type.

This process keeps harmful substances out of landfills. It also supports waste control targets set by local councils and state bodies.

Without proper scrapping, the auto industry would face growing waste problems.

Data from Old Cars Shapes New Designs

Automakers study failure patterns. They track which parts fail early and which last longer. Data from scrapped cars helps this work.

By examining wear points, designers improve future models. They adjust materials, layouts, and protection features.

Scrapped cars act like history books for engineers. Each one tells a story about use, climate, and stress.

This feedback loop shapes safer and longer-lasting vehicles.

Electric Vehicles Increase the Role of Scrapping

Electric vehicles change how scrapping works. Batteries hold lithium, cobalt, and nickel. These materials carry high demand.

Battery recycling now forms a growing sector. Old electric cars supply materials for new battery packs. This reduces reliance on overseas mining.

Australia has strong interest in this area due to local mineral resources and recycling research.

As electric vehicle numbers rise, scrapped cars will matter even more.

Jobs Depend on Vehicle Scrapping

The scrapping sector supports many roles. These include tow operators, dismantlers, metal processors, logistics workers, and compliance officers.

Each scrapped car passes through several hands. This activity supports local employment, especially in outer suburbs and industrial zones.

The modern auto industry includes these workers, even if they do not build new cars.

Environmental Pressure Makes Scrapping Essential

Governments now track emissions across full product life cycles. Cars form part of this accounting.

Recycling metals from scrapped vehicles cuts energy use. It also lowers emissions linked to mining and transport.

Australia faces climate targets at state and federal levels. Vehicle recycling supports these goals.

Scrapped cars help reduce the footprint of the entire auto sector.

A Practical Link Between Owners and Industry

Car owners often feel stuck when a vehicle reaches the end of its life. It may not pass inspection. It may not sell privately. Leaving it unused only creates clutter.

This is where removal services fit into the wider picture. A service such as Primo Car Removal connects owners with licensed scrap handling. It ensures vehicles enter proper processing streams rather than sitting idle. This link keeps materials flowing back into manufacturing and repair channels. For people searching for Top Car Removal Sydney options, this step supports the broader auto system while clearing unused vehicles from homes and streets.

This process does not stand apart from the industry. It feeds directly into it.

Scrapped Cars Support Circular Manufacturing

The auto industry now focuses on circular use. This means materials cycle back into production rather than ending as waste.

Scrapped cars form a core part of this loop. Steel becomes new panels. Aluminium becomes engine parts. Plastics become interior trim.

This system reduces pressure on natural resources and supports long term production stability.

Australia continues to expand this model across sectors.

Conclusion

Scrapped cars still matter. They support steel supply, parts reuse, waste control, job creation, and future vehicle design. They also play a growing role in electric vehicle development.

The modern auto industry does not only move forward through new cars. It also relies on how old cars exit the road.

Each scrapped vehicle contributes to what comes next. That is why the final stage of a car life remains just as important as the first.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness