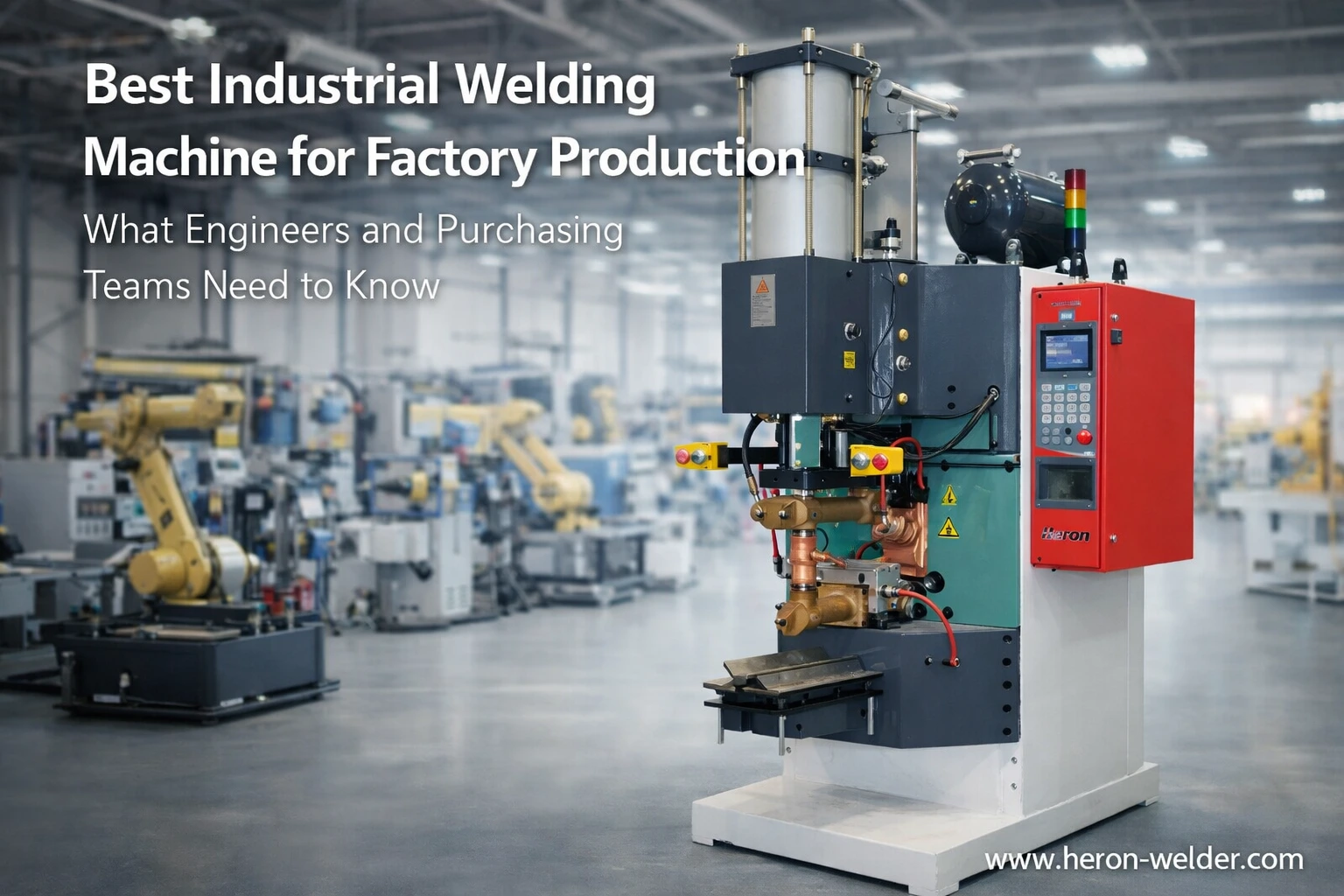

Spot Welding Equipment: Precision Solutions for Modern Manufacturing

In today’s fast-paced manufacturing environment, efficiency, precision, and reliability are non-negotiable. Spot welding equipment plays a critical role in the assembly of metal components, particularly in automotive, aerospace, electronics, and industrial applications. By offering consistent weld quality and rapid cycle times, spot welding has become a cornerstone of modern metal-joining processes. At Heron Welder, we provide state-of-the-art spot welding machines and integrated automation solutions tailored to meet the exacting needs of OEMs, manufacturing engineers, and production line integrators.

What Is Spot Welding Equipment?

Spot welding is a form of resistance welding where two or more metal sheets are joined by applying heat generated from electrical resistance. A spot welding machine uses electrodes to clamp the metal pieces and pass a controlled current through the contact area, causing the metal to melt and fuse. The result is a small, high-strength weld at precise locations, commonly referred to as a "spot."

Modern spot welding equipment ranges from simple manual units to advanced automated systems integrated with production lines. Key components typically include:

-

Electrodes: Copper alloy tips that transfer current and apply pressure to the workpieces.

-

Transformers or MFDC power sources: Deliver precise electrical current for weld formation.

-

Control systems: Programmable controllers or PLCs that manage timing, current, and pressure.

-

Cooling mechanisms: Maintain electrode performance and prevent overheating during high-volume operations.

Heron Welder specializes in delivering robust spot welding equipment with advanced controls and automation compatibility for consistent, high-quality welds.

Principles of Spot Welding

Understanding the underlying principles of spot welding helps engineers optimize their processes. The spot welding cycle typically involves four stages:

-

Clamping: Electrodes apply pressure to hold the metal sheets together.

-

Current Application: A precise pulse of electrical current passes through the metal, generating heat due to electrical resistance.

-

Weld Formation: The heat melts the metal at the contact point, forming a nugget as the current stops.

-

Cooling: Pressure is maintained while the weld cools, ensuring strength and stability.

The size and quality of the weld nugget depend on factors such as electrode force, current intensity, duration, and metal thickness. Heron’s spot welding systems provide full parameter control to ensure repeatable weld quality across production runs.

Applications of Spot Welding Equipment

Spot welding is widely used in industries that demand precision and high throughput. Common applications include:

-

Automotive Manufacturing: Joining sheet metal panels in car bodies, chassis, and battery enclosures.

-

Aerospace Components: Assembling lightweight aluminum or steel panels for structural integrity.

-

Electronics and Appliances: Fabricating battery packs, metal casings, and electronic enclosures.

-

Industrial Equipment: Constructing machinery frames, storage tanks, and metal furniture.

Heron Welder’s solutions are designed to integrate seamlessly into existing production lines, including robotic automation cells, ensuring maximum efficiency and minimal downtime.

Types of Spot Welding Equipment

Spot welding equipment can be classified based on power supply and automation level:

1. AC Spot Welding Machines

Traditional machines that use alternating current transformers. Suitable for general-purpose applications with moderate production rates.

2. MFDC Spot Welding Machines

Medium-Frequency Direct Current (MFDC) machines provide precise control over weld energy, ideal for thin materials, stainless steel, and aluminum. MFDC systems reduce energy consumption and improve consistency.

3. Capacitor Discharge (CD) Spot Welders

Used for very thin metals or specialized applications such as battery tabs, CD welders discharge stored energy rapidly, producing fast, controlled welds with minimal heat distortion.

4. Automated Spot Welding Lines

Robotic or gantry-mounted spot welders integrated into production lines for high-volume, repeatable operations. These systems include multi-axis motion control, vision-guided positioning, and real-time quality monitoring.

Heron Welder offers the full spectrum of spot welding solutions, from manual units to fully automated production lines, catering to both low-volume custom fabrication and high-volume OEM assembly.

Best Practices for Spot Welding

To achieve reliable and long-lasting welds, manufacturers should follow best practices:

-

Electrode Maintenance: Regularly dress electrodes to prevent pitting and maintain consistent weld quality.

-

Parameter Optimization: Adjust current, pressure, and weld time according to material type and thickness.

-

Material Preparation: Ensure clean surfaces to reduce contamination and improve weld strength.

-

Process Monitoring: Utilize intelligent controllers to log parameters, detect faults, and ensure compliance with production standards.

By combining these practices with Heron’s advanced spot welding equipment, manufacturers can improve throughput, reduce scrap, and ensure consistent product quality.

Spot Welding vs. Other Welding Methods

Compared to MIG, TIG, or laser welding, spot welding offers unique advantages:

| Feature | Spot Welding | MIG/TIG Welding | Laser Welding |

|---|---|---|---|

| Speed | Extremely fast for thin sheets | Slower | High-speed, but higher setup cost |

| Automation | Easily automated | Moderate | Requires precise fixturing |

| Material Thickness | Ideal for thin to medium sheets | Flexible | Thin to medium, precise |

| Heat Input | Localized, minimal distortion | Higher | Focused, but requires laser optics |

| Cost | Economical for high volume | Higher | Higher equipment cost |

Spot welding’s localized heat and speed make it the preferred choice for high-volume sheet metal assembly, particularly in automotive and industrial production.

Why Choose Heron Welder for Spot Welding Equipment?

Heron Welder is a global leader in resistance welding technology, delivering:

-

Customizable Solutions: Manual, semi-automatic, or fully automated systems tailored to your production needs.

-

Advanced Controls: MFDC and capacitor discharge technologies for precise, repeatable welds.

-

Robust Build Quality: Machines engineered for long operational life and minimal maintenance.

-

Automation Integration: Solutions compatible with robotics, conveyors, and factory automation systems.

With Heron, manufacturers gain not just equipment, but a partner committed to optimizing productivity, quality, and operational efficiency.

FAQs About Spot Welding Equipment

1. What metals can be spot welded?

Primarily steel, stainless steel, and aluminum sheets. MFDC systems are ideal for thin or highly conductive metals like aluminum.

2. How thick can the materials be for spot welding?

Typically, 0.5 mm to 6 mm for most sheet metals. For thicker materials, multi-pass or specialized welding equipment may be required.

3. How often should electrodes be maintained?

Electrodes should be inspected and dressed regularly, depending on usage, typically every few thousand welds to maintain quality.

4. Can spot welding be automated?

Yes. Robotic or gantry systems allow fully automated, high-volume spot welding with consistent quality and traceability.

5. What industries benefit most from spot welding?

Automotive, aerospace, electronics, industrial machinery, and metal fabrication industries rely heavily on spot welding for precision assembly.

Take Your Spot Welding to the Next Level

Investing in the right spot welding equipment can transform your production line’s efficiency and product quality. Heron Welder offers a full range of manual, MFDC, CD, and automated spot welding solutions, designed to meet the demands of OEMs, engineers, and factory automation integrators.

Contact Heron today to request a quote or consult our experts for a customized welding and automation solution tailored to your manufacturing needs.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness